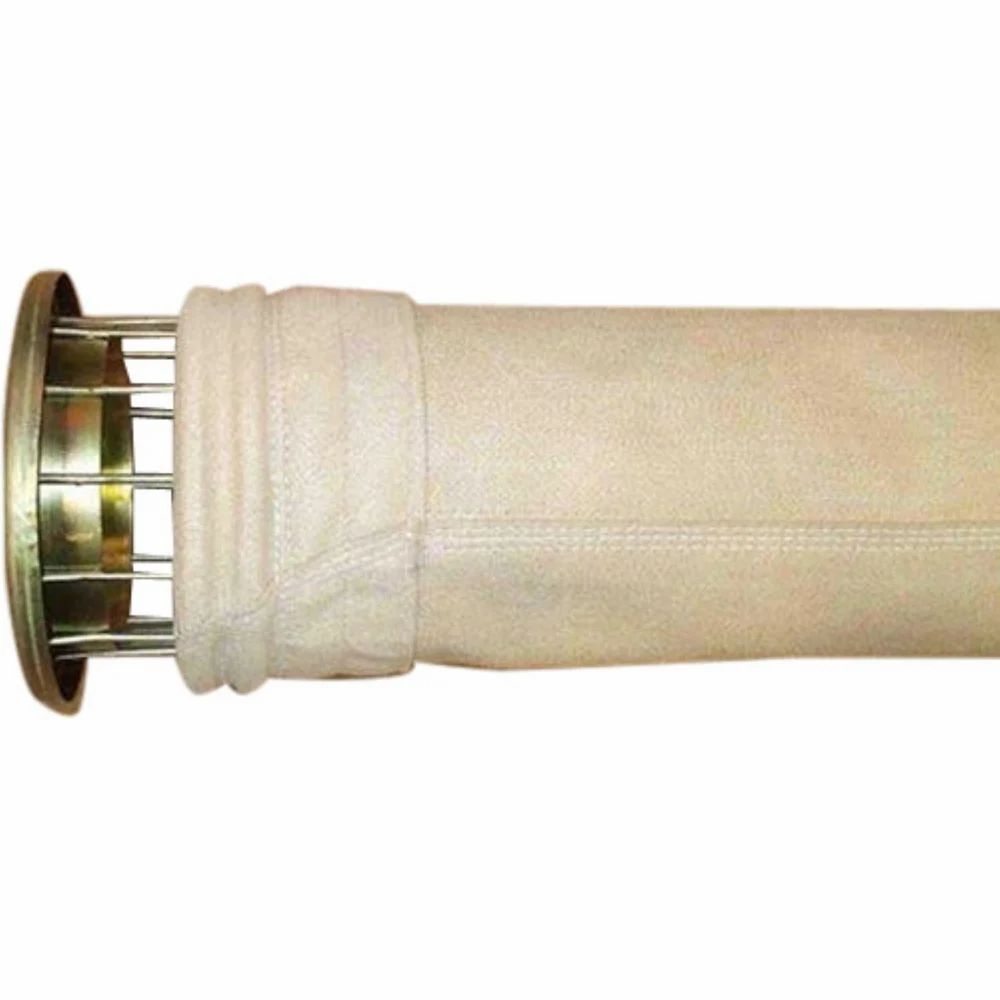

à¤à¥à¤°-बà¥à¤¨à¤¾ फ़िलà¥à¤à¤° बà¥à¤

Price 400 आईएनआर/ टुकड़ा

MOQ : 100 टुकड़ाs

à¤à¥à¤°-बà¥à¤¨à¤¾ फ़िलà¥à¤à¤° बà¥à¤ Specification

- दक्षता (%)

- 100%

- प्रतिरोध

- उच्च

- उपयोग

- औद्योगिक

- साइज

- स्वनिर्धारित

- ऊंचाई

- मीटर (m)

- प्रॉडक्ट टाइप

- गैर-बुना फ़िल्टर बैग

- मोटाई

- मीटर

- लम्बाई

- मीटर (m)

- चौड़ाई

- मीटर (m)

à¤à¥à¤°-बà¥à¤¨à¤¾ फ़िलà¥à¤à¤° बà¥à¤ Trade Information

- Minimum Order Quantity

- 100 टुकड़ाs

- भुगतान की शर्तें

- कैश इन एडवांस (CID)

- आपूर्ति की क्षमता

- 1000 प्रति महीने

- डिलीवरी का समय

- 10 दिन

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About à¤à¥à¤°-बà¥à¤¨à¤¾ फ़िलà¥à¤à¤° बà¥à¤

Non-Woven Filter Bags are a type of filtration media used in various industries, including chemical, pharmaceutical, food and beverage, and wastewater treatment. Here's a concise overview:

Key Features- Material: Non-woven fabric, typically made from polypropylene (PP), polyester (PET), or polyamide (PA)

- Structure: Randomly arranged fibers, providing a high surface area for filtration

- Filtration Mechanism: Mechanical filtration, capturing particles and contaminants within the fabric

Types of Non-Woven Filter Bags1. Spunbond: High-strength, high-temperature applications

2. Meltblown: High-efficiency filtration, often used in combination with spunbond

3. Needle-Punched: High-porosity, high-flow applications

Advantages- High Filtration Efficiency: Captures particles and contaminants effectively

- Low Pressure Drop: Minimizes energy losses and reduces operating costs

- Easy Installation and Maintenance: Simplifies filter replacement and reduces downtime

Considerations- Compatibility: Ensure the filter bag material is compatible with the process fluid or gas

- Operating Conditions: Consider temperature, pressure, and flow rate when selecting a filter bag

- Regulatory Compliance: Ensure the filter bag meets relevant industry standards and regulations

Superior Customization

We cater to your unique industrial requirements by offering Non-Woven Filter Bags in customizable dimensions, including height, width, length, and thickness. Each bag is tailored to ensure optimal performance and a precise fit every time, regardless of your system's configuration.

Exceptional Filtration Efficiency

With a filtration efficiency of 100%, our Non-Woven Filter Bags are engineered to excel in demanding environments. The high resistance properties ensure durability and consistent filtration over extended operating periods, helping safeguard your processes.

Comprehensive Service Capabilities

As a manufacturer, supplier, and service provider based in India, we deliver end-to-end solutions. From design consultation to after-sales support, our expertise maximizes both product quality and customer satisfaction for all your industrial filtration needs.

FAQ's of Non-Woven Filter Bags:

Q: How do Non-Woven Filter Bags benefit industrial applications?

A: Non-Woven Filter Bags help maintain clean air and liquid systems by efficiently filtering out contaminants. Their high resistance and 100% efficiency make them integral for industrial operations where reliability and performance are critical to protect machinery and ensure product quality.Q: What customization options are available for the filter bags?

A: We offer full customization on the height, width, length, and thickness of our filter bags. Clients simply provide their preferred measurements, and we manufacture each bag to fit specific system requirements, ensuring optimal filtration and seamless integration.Q: When should you replace or maintain these filter bags?

A: Regular inspection and scheduled maintenance are recommended to uphold maximum efficiency. Over time, filter bags can accumulate deposits, requiring cleaning or replacement depending on the degree of clogging and the nature of the filtered material.Q: Where are these Non-Woven Filter Bags manufactured?

A: Our filter bags are manufactured in India, in facilities that adhere to stringent quality control standards. We supply nationwide and offer consultation services to ensure the best fit for diverse industrial sectors.Q: What is the process for ordering customized filter bags?

A: To order, customers need to specify their desired height, width, length, and thickness. Our team assists in finalizing specifications and guides clients through production timelines, from initial design consultation to delivery and installation.Q: How are these filter bags typically used in industrial settings?

A: They are used for air or liquid filtration in systems requiring efficient contaminant removal. Common applications include dust collection, liquid filtration in chemical processing, and ensuring clean environments for manufacturing operations.Q: What are the primary benefits of choosing your filter bags over standard options?

A: Our filter bags offer tailored dimensions and high filtration efficiency, which helps reduce downtime, extend equipment lifespan, and enhance operational productivity. This customization leads to improved performance compared to off-the-shelf alternatives.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in फ़िल्टर बैग Category

PTFE डस्ट कलेक्टर फिल्टर बैग

उपयोग : औद्योगिक

लम्बाई : मीटर (m)

मूल्य या मूल्य सीमा : आईएनआर

चौड़ाई : मीटर (m)

मूल्य की इकाई : यूनिट/यूनिट

मोटाई : मीटर

Nomex फ़िल्टर बैग

उपयोग : औद्योगिक

लम्बाई : मीटर (m)

मूल्य या मूल्य सीमा : आईएनआर

चौड़ाई : मीटर (m)

मूल्य की इकाई : यूनिट/यूनिट

मोटाई : मीटर

औद्योगिक फ़िल्टर बैग

उपयोग : औद्योगिक

लम्बाई : मीटर (m)

मूल्य या मूल्य सीमा : आईएनआर

चौड़ाई : मीटर (m)

मूल्य की इकाई : टुकड़ा/टुकड़े

मोटाई : मीटर

प्रदूषण नियंत्रण उद्यम

GST : 06BHCPA5127L1ZL

GST : 06BHCPA5127L1ZL

प्लाट न. 1890, जीवन नगर, गौंछी, नियर सेक्. 55, बल्लभगढ़,फरीदाबाद - 121004, हरयाणा, भारत

फ़ोन :08045800910

|

POLLUTION CONTROL ENTERPRISES

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

जांच भेजें

जांच भेजें