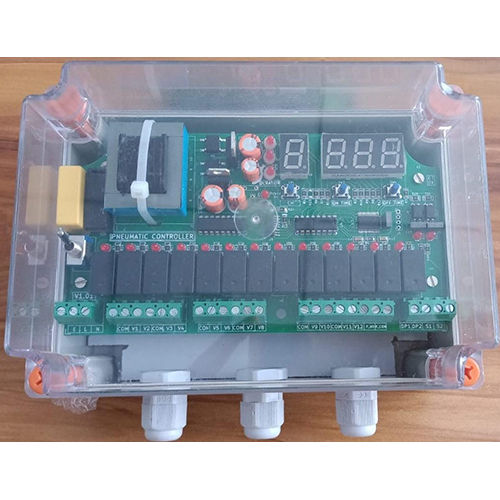

डिà¤à¤¿à¤à¤² सà¥à¤à¥à¤µà¥à¤à¤¸ à¤à¤¾à¤à¤®à¤°

Price 10000 आईएनआर/ Unit

MOQ : 10 Units

डिà¤à¤¿à¤à¤² सà¥à¤à¥à¤µà¥à¤à¤¸ à¤à¤¾à¤à¤®à¤° Specification

- टाइप करें

- मैकेनिकल टाइमर

- मटेरियल

- मेटल

- रंग

- स्लेटी

- उपयोग

- औद्योगिक

डिà¤à¤¿à¤à¤² सà¥à¤à¥à¤µà¥à¤à¤¸ à¤à¤¾à¤à¤®à¤° Trade Information

- Minimum Order Quantity

- 10 Units

- भुगतान की शर्तें

- कैश इन एडवांस (CID)

- आपूर्ति की क्षमता

- 1000 प्रति महीने

- डिलीवरी का समय

- 10 दिन

- मुख्य निर्यात बाजार

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About डिà¤à¤¿à¤à¤² सà¥à¤à¥à¤µà¥à¤à¤¸ à¤à¤¾à¤à¤®à¤°

A Digital Sequence Timer is an electronic device used to control a sequence of events or operations in a specific order and timing. Here's a concise overview:

Key Features- Purpose: Automates processes by triggering outputs in a predefined sequence.

- Operation: Uses digital logic to execute a series of steps, often with adjustable timing and inputs.

- Applications: Industrial automation, machinery control, testing equipment, and more.

Common Specifications- Inputs: Digital signals (e.g., start, stop, reset) or sensor inputs.

- Outputs: Relay, transistor, or optocoupler outputs to control devices.

- Sequence Control: Programmable steps, timing, and logic.

- Display: LED/LCD for status and programming.

- Power Supply: Typically 24V DC or 220V AC.

Types1. Fixed Sequence Timer: Predefined sequence, often with fixed timing.

2. Programmable Timer: User-configurable sequence and timing.

3. PLC-Based: Integrated with programmable logic controllers for complex automation.

Advantages- Automation: Reduces manual intervention and errors.

- Flexibility: Programmable for different sequences.

- Reliability: Digital control ensures consistent timing.

Considerations- Programming: May require knowledge of specific programming languages (e.g., ladder logic).

- Environment: Industrial-grade timers are designed for harsh conditions.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in डिजिटल अनुक्रम टाइमर Category

PCE-10CH -24V डीसी डिजिटल सीक्वेंस टाइमर

टाइप करें : मैकेनिकल टाइमर

थ्योरी : इलेक्ट्रोनिक

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

उपयोग : औद्योगिक

मटेरियल : मेटल

PCE-12CH डिजिटल सीक्वेंस टाइमर

टाइप करें : मैकेनिकल टाइमर

थ्योरी : इलेक्ट्रोनिक

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

उपयोग : औद्योगिक

मटेरियल : मेटल

PCE- 24CH डिजिटल सीक्वेंस टाइमर

टाइप करें : मैकेनिकल टाइमर

थ्योरी : इलेक्ट्रोनिक

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

उपयोग : औद्योगिक

मटेरियल : मेटल

प्रदूषण नियंत्रण उद्यम

GST : 06BHCPA5127L1ZL

GST : 06BHCPA5127L1ZL

प्लाट न. 1890, जीवन नगर, गौंछी, नियर सेक्. 55, बल्लभगढ़,फरीदाबाद - 121004, हरयाणा, भारत

फ़ोन :08045800910

|

POLLUTION CONTROL ENTERPRISES

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

जांच भेजें

जांच भेजें